Car Exterior Parts—Cleaning and Activation of Complex Multi-Materials

Car exterior parts are today made of complex combinations of materials ranging from metal tailored blanks to sheet molded compounds (SMC) and glass fiber reinforced plastics (GFRP) to hybrid plastics. The starting materials have very different surface qualities. Plasma pretreatment is a key technology for achieving stable material combinations and high-quality surface finishes with secure adhesion. It points the way ahead, both economically and ecologically.

Topics on this Page:

Paint touch-ups Polymer Paint Release Adhesion on car door handles Reinforcement of Tires

Successful applications of Plasma in car exterior parts

- Surface activation prior to painting of bumpers made of PP/EPDM compounds

- Openair-Plasma® pre-paint surface pretreatment of fenders made of SMC

- Plasma microfine cleaning of ceramic coatings prior to glazing

- Plasma microfine cleaning of aluminum frames for waterproof bonding of glass sunroofs

- Polymer paint release coatings

Lighter components—secure adhesion and structural reinforcement

E.g., tailored blanks are metal panels made of layers of different material grades in varying thicknesses and strengths. They are supplied as semi-finished products for manufacturing car exterior parts. These tailored metal panels are selectively reinforced by additional material layers at points or areas which will be exposed to high stress loads in service.

Their structural strength can be improved still further using special reinforcing adhesives. In this process step, Openair-Plasma® pretreatment assures secure adhesion of the material layers. This combination provides distinct advantages in terms of low weight of the components plus increased crash safety.

Bonding to dirt-repellent nano-coatings

Modern lotus-effect nano-coatings and ultra-hydrophobic topcoats make it possible to produce highly dirt-repellent surfaces. The downside is that such surfaces have a very low surface tension.

Various adhesives manufacturers claim to offer products capable of bonding to such coatings. However, such adhesives can only be used within a narrow process window (temperature or humidity) and have a limited open time.

Pretreatment of hydrophobic and non-polar coatings with Openair-Plasma® enables efficient and selective activation of surfaces, resulting in long-term adhesion. This simple method makes it possible to achieve reliable results with VOC-free adhesives with longer open times, for example when bonding door seals, trim strips and model nameplates.

Perfect adhesion to the original clearcoat

Paint systems for autobodies consist of several layers: e-coat, primer, basecoats and clearcoat. Painting defects and particle inclusions require work-intensive touch-up procedures (masking, sanding, repainting). Since the original clearcoat (topcoat) has a low surface tension, getting new coats to adhere to it is only possible with the help of pretreatment.

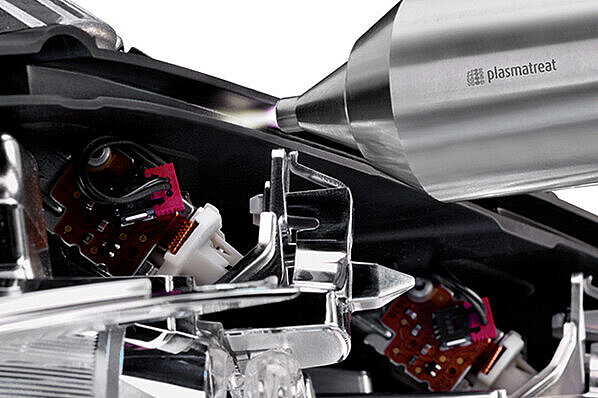

Selective plasma pretreatment is an economical and efficient alternative to retreating the entire car body. The Openair-Plasma® process from Plasmatreat can be used for localized touch-ups and as a pretreatment prior to painting the complete autobody. Low-pressure chambers are not required with Openair-Plasma®.

Polymer paint release coatings through low-pressure plasma process

The removal of overspray removal can be greatly improved by applying a release coating to surfaces that need to be cleaned. This involves applying a thin layer of paint-resistant polymer to the polar metal surface (usually galvanized steel). This coating greatly reduces the adhesion of paints and organic coatings. These paint release coatings can efficiently be applied using the Aurora® low pressure plasma process to provide highly durable and excellent release performance.

Plasmatreat has partnered with the Fraunhofer Institute IFAM to develop this kind of high-performance paint release coating, called PermaCLEAN Plus®, as a service.

Paintshop tools: Paint release coatings against overspray

In industrial paint shops, there is always a certain amount of overspray that has to be cleaned up and carefully removed. Overspray collects on the filters, on floors, on the conveyor, and on part racks. After several painting cycles, these paint deposits can begin to flake off and can contaminate freshly painted parts. Consequently, at regular cleaning intervals, the accumulated paint overspray needs to be removed from the surrounding surfaces and from the filtration system. Normally, this is done using high-pressure water jets along with laborious manual scraping.

Best paint adhesion on plastic car door handles

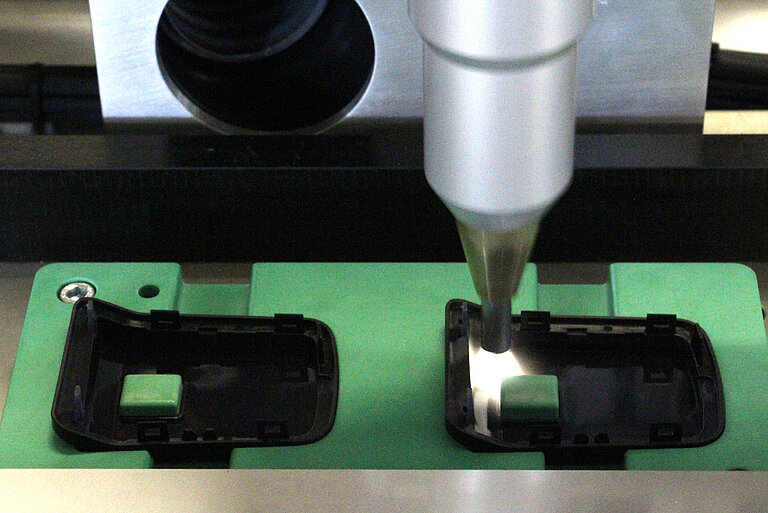

Car door handles can be pre-treated effectively with either atmospheric plasma (Openair-Plasma®) or by low-pressure plasma process Aurora, depending on whichever method is most appropriate for the throughput required and the specific paint technology used. Atmospheric plasma pre-treatment is especially well suited for flatline painting processes where the Openair-Plasma® nozzles can be installed directly above the painting line.

If painting is performed by robots and on spindle-conveyor type machines, the door handles are frequently conveyed through the paint booth using part carriers. The Aurora low-pressure pre-treatment method is well suited to this kind of process. The part surface of door handles for complete trays of parts can be evenly and reliably activated in the Aurora pre-treatment chamber.

High demands on car door handles

Exterior automotive door handles are subjected to a number of mechanical and environmental stresses. They are constantly exposed to humidity, UV light and widely varying temperatures. They also undergo physical stresses, and the effects of perspiration and dirt.

In order to save weight, reduce cost and improve safety, car door handles are usually made of plastics such as PBT, fiber-reinforced PA, or ABS. These plastic parts then need to be painted to achieve an optimal look and feel.

Interesting success stories in this field

Reinforcement of automobile tires using polyamides (e.g. Kevlar® mesh)

An automobile tire consists of the tread and the tire skeleton. More than 200 different materials are used in manufacturing automobile tires, including oils, steel, sulphur compounds, Kevlar®, polyester and up to 80 different grades of rubber, aramid, zinc, resin and silica.

To increase the tire’s speed rating and handling, the tire tread is reinforced with Kevlar® (aramid). Achieving a secure bond between the tread material and the Kevlar® meshing so the tire can withstand high g-forces is of crucial importance. In mass production, this adhesion is promoted by pre-treating the aramid mesh with caustic sulfuric acid.

Safer, more reliable material bonding thanks to Aurora plasma

Pre-treatment with Aurora low-pressure plasma provides a more reliable and environmentally friendly alternative for this hazardous chemical process. Plasma effectively functionalizes the surface of the aramid mesh for the subsequent vulcanization process.