Openair-Plasma® Jets – specific systems for different requirements

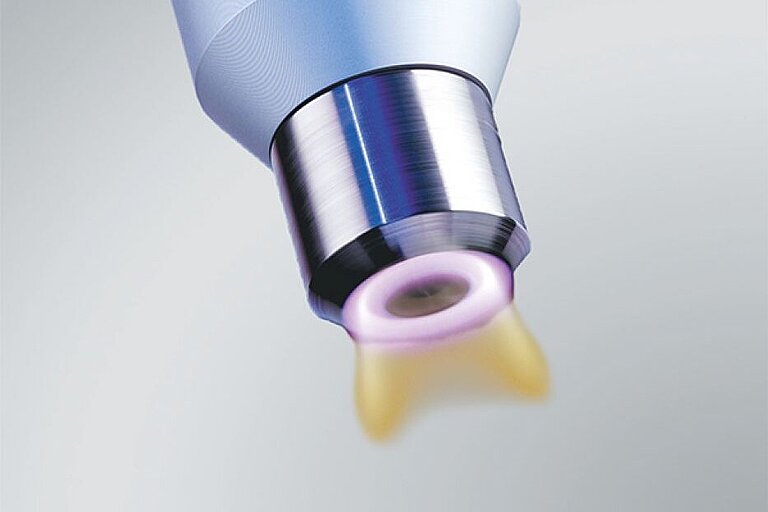

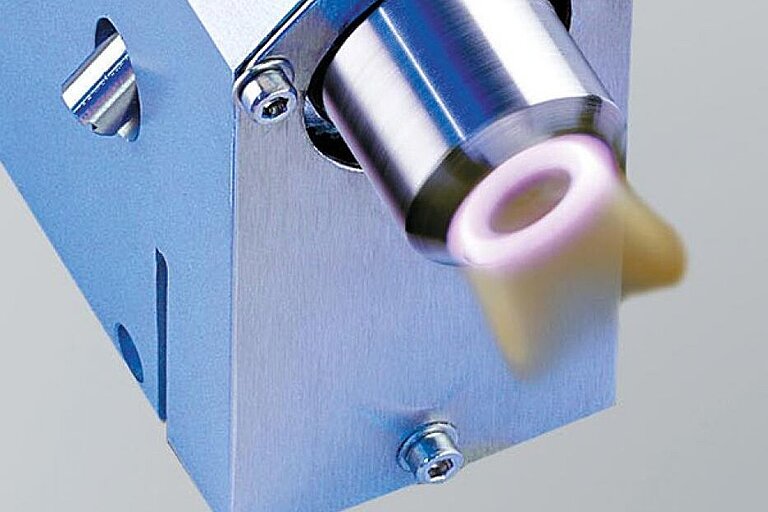

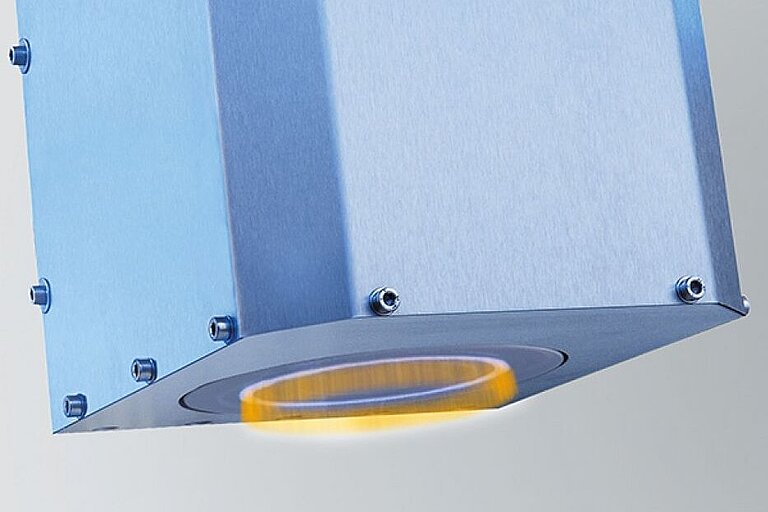

The plasma jets directed onto the material are used to generate and spread the plasma (cold plasma is generated). The plasma is generated inside the jet by a high voltage between a stator and a rotor and is blown out through the jet head using working gas. With its patented jet systems, Plasmatreat has developed extremely robust, highly effective tools for industrial surface treatment. Both single jets and rotating plasma systems are available as plasma sources.

Single jets have a relatively small outlet angle and are therefore better suited for the treatment of narrow profiles. Rotating plasma systems, which distribute the pretreatment effect evenly onto over the larger work width as a result of the rotation principle, are better suited for wider processing surfaces.

FEATURES &

ADVANTAGES

Openair-Plasma® in industrial processes:

- Quality: The process achieves a 100% cleaning or activation effect of the complete material structure.

- Efficiency: Components can be treated selectively and directly processed. In this context, plasma pretreatment opens up large process windows during further processing.

- Automatization: The fully automated inline systems, which produce high-quality results, can be easily integrated into existing production lines. This streamlines production processes, which leads to a cost reduction.

- Environmentally friendly: Openair-Plasma® makes production more ecological, because the use of environmentally harmful chemicals (primers) can be completely eliminated in processes such as bonding. If renewable sources of energy are used, the whole process can take place with zero CO2 emissions.

- Reproducibility: Modern production monitoring tools ensure well-coordinated and highly-precise surface treatment with precise handling of modules and components, including measures that achieve the most efficient cycle rates.